Home > Factory Automation > Handling Robot

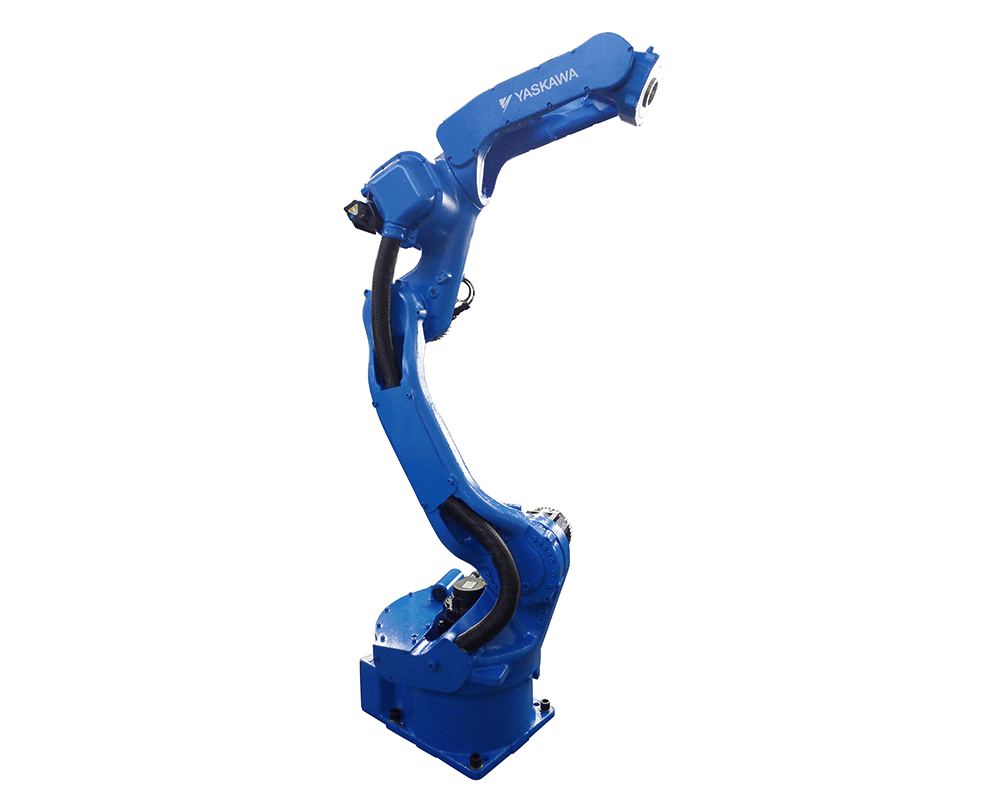

Handling Robot

ITO Thailand supplies a wide range of Yaskawa Motoman industrial handling robots, with arm models for high-speed precision assembly and small part handling for any industry type

What Is It Used For

The Yaskawa Motoman Handling Robots line include high-performance six-axis robots; flexible seven-axis manipulators; dual-arm robots with 15-axis and amazing human-like motion; and a family of four-axis SCARA robots. These models, especially the new generation SDA (15 axis) and SIA (7-axis) robots, offer cell space optimization, dexterity with outstanding range of motion and tooling simplification. For machining applications, ensuring accuracy and consistency is critical. Yaskawa Motoman robotics and automation systems can deliver the repeat-ability and precision required for a variety of machining applications. Our handling robot line features seven-axis models that can mount virtually anywhere, including in the machine. We also offer our seven axis MotoRail robots when a larger work envelope is needed. To enhance our solutions and provide even greater flexibility, Yaskawa Motoman has partnered with Mikrolar, Inc. on the development and marketing of high-precision positioning systems. Mikrolar's hexapod system, combined with Yaskawa Motoman robots, offers high-load capacity and range of movement unique to the machining industry. ITO Thailand offers robotic automation solutions as well as production line engineering services that feature the Yaskawa Motoman line of robots to their customers.

Misc Info

Yaskawa Motoman assembly robots excel at the following applications:

- Part Location

- Part Identification

- Part Sortation

- Flexible Feeding

- Bowl Feeding

- Conveyance

- End-Effectors

- Tool Changing

- Force Sensing

- Part Fastening or Joining

- Presence / Absence

- Error Proofing

- Visual Inspection